In the current competitive construction sector, construction procurement is no longer a back-office function. It is the backbone of a successful building project. In simple terms, procurement in construction is the strategic practice of sourcing materials and hiring contractors. Procurement ensures projects are completed on time, within budget, and to quality standards.

If you’ve ever wondered, “what is procurement in construction?”, think of it as the glue that keeps a project running smoothly. From a single bag of cement to a multi-million-dollar crane, procurement ensures that everything arrives on time, at the right place, and within budget. This explanation is for your understanding, but we describe the procurement process in detail below so you can learn it and understand it better.

What is Procurement in Construction?

The simplest possible answer to the question about the meaning of procurement is: A systematic way of obtaining all the things needed by a project within time, cost, and quality specifications.

Procurement Meaning in Construction

Procurement in construction is not just about buying materials; it also involves planning, selecting suppliers, managing contracts, and controlling costs throughout the project lifecycle. It works from external sources to execute a construction project efficiently.

For example, in the GCC(Gulf Cooperation Council) region, mega projects like NEOM in Saudi Arabia rely on strategic supplier selection and risk profiling even before the design phase is finalized. This ensures timely delivery and quality compliance, reducing the risk of delays and cost overruns.

Key Components of Construction Procurement

Technical Perspective

- Establishing project requirements → Defining what materials, services, or expertise will be needed in the project.

- Establishing a procurement framework → Defining timelines, budgets, quality controls, and compliance requirements.

- Establishing procurement contracts → It involves creating contracts with suppliers and subcontractors to ensure accountability and delivery.

Managerial Perspective

- Assessment of suppliers other than on cost in terms of reliability, capacity, and sustainability.

- Streamlining logistics so that materials come when they are needed (early = storage problems, late = time wastage).

- Risk mitigation by ensuring transparency of documentation, use of performance clauses, and contingency plans.

Why is procurement so important?

Understanding what procurement means, its processes, and management strategies is essential for developers, contractors, and project managers. It helps with project scheduling and budgeting, including what you purchase, how you purchase, and whom you buy from.

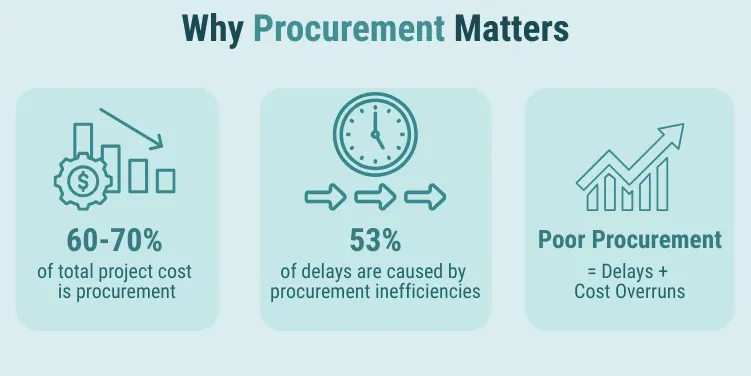

According to the Construction Management Association of America, “Large-scale construction, procurement activities can account for 60–70% of total project costs.”

Get procurement right, and projects will be on schedule, within budget, and with fewer surprises. Get it wrong, and deadlines will start to slip, costs will go through the roof, and stress levels will rise. Modern construction is also evolving with digital tools and sustainable sourcing, making procurement smarter and more efficient.

How Construction Procurement Process Drives Project Success

A well-executed project adheres to a roadmap, and that roadmap is the construction procurement process. This process ensures that the appropriate resources are located, procured, and managed throughout the project completion. Missing or hurrying any of the steps is likely to result in expensive delays. We break down the construction procurement process into clear, actionable phases:

Requirement Definition

The path starts by spelling out the project requirements and identifying the materials, services, and project scope. This implies a briefing on the extent of works, quantities, specifications, budgetary limits, and schedules. It is like making up the shopping list before going to the store, albeit the store in this case may include cranes, steel beams, and sophisticated HVAC systems.

Supplier Selection

This is the process of shortlisting suppliers based on capability, cost, quality, and past performance. Procurement departments also consider sustainability and risk when selecting suppliers who can deliver these in real-world conditions.

Contracting

When a supplier is selected, the procurement process in construction management enters the formal contracting phase. In this step, clear terms are drafted, deliverables are defined, performance benchmarks are set, and penalties are imposed for delays or non-performance. It is basically about securing the project by establishing sound legal and business institutions. It’s signing agreements and finalizing terms.

Execution & Monitoring

Now we proceed to managing deliveries, workflows, and resource compliance. Purchasing agents need to be vigilant in reviewing construction contracts to ensure they comply with specifications, time limits, and budgetary requirements. It requires sufficient planning, coordination, and controls; without it, even the finest of suppliers may not succeed.

Payment & Closure

At last, the procurement agent completes financial transactions and closes contracts. They verify delivery and performance first, then clear the supplier payments and close the contract. The agent will maintain strong supplier relationships, and the data gathered during closure will be used in future projects.

✅Did you know?

According to Autodesk Construction Cloud (2024), 53% of construction delays are caused by procurement inefficiencies, highlighting the importance of proper planning.

Procurement in Construction Management

Procurement in construction management is a deep and broad process. Effective management ensures that projects run smoothly by integrating on-ground operations with strategic oversight. Two major roles facilitate this:

- Procurement managers: Oversee sourcing, supplier evaluation, and risk management.

- Contract administrators: Ensure contracts are followed, and budgets are controlled.

Key Roles of the Procurement Manager

- Procurement Risk Profile: Anticipating delays or supplier issues

- Quality control: Verifying materials meet standards.

- Purchasing and logistics: Ensuring timely delivery.

- Cost control: Preventing budget overruns.

In construction procurement, integrating real-time vendor data with on-site monitoring can help prevent costly mistakes.

👉 Learn more about the Importance of Procurement Management.

Key Roles of Contract Administrators

Managers oversee strategy, and contract administrators make sure the contractual terms are implemented properly. Their roles are;

- Prepare and negotiate contracts to protect schedules, budgets and quality requirements.

- Establish strict quality control through accountability on agreed specifications with suppliers.

- Track development metrics and raise red flags on issues before they have a chance to become project-level roadblocks.

👉 Read our in-depth Guide on Contract Management in Procurement.

Why Integration is Important

Effective procurement management relies on field realities and supplier information interconnected with one another. To support procurement in construction in a professional way, it is essential to humanize on-ground perspectives as well as performance indicators of vendors.

In this manner, decisions become not only cost-effective but also realistic, and projects tend to be in a balanced state between the spreadsheets and field conditions.

Types & Methods of Construction Procurement

Not all projects proceed on the same path. The types of construction procurement and the procedures involved may be different with regard to scale, complexity and client objectives.

Types of Construction Procurement

Traditional

The traditional path is where configuration and construction are treated independently. Architects finalize the design and contractors bid out its implementation. Design completed first, then construction procured. This method provides the ability to plan in detail, but can lengthen schedules.

Design & Build

This model is one where only a single contractor is in charge of design and construction. It is quicker and more coordinated, and there may be less control of the design by the clients.

EPC(Engineering, Procurement, and Construction)

Common in large infrastructure and energy projects, the EPC model leaves everything to a single party in charge, including engineering, procurement and construction. Since it is more efficient and minimizes risk to the client, it usually has a higher initial cost.

Management Contracting

In this case, the project manager coordinates with multiple subcontractors. They manage various trade contracts and enable flexibility & execution in phases, but it requires close supervision.

Common Procurement Methods in Construction

Open bidding, negotiated contracts, and selective tendering.

Open Bidding

Anyone can submit tenders, and the process is competitive and transparent. However, it can also attract unqualified bidders.

Selective Tendering

Only pre-qualified contractors are invited, which means that bids will be provided by qualified suppliers but with reduced competition.

Negotiated Contracts

A contractor is appointed directly, most often used in specialized and urgent projects. Although it is faster, it can hamper the competitiveness of prices.

The type and method of procurement may be the difference between the success or failure of any niche project. For specialized projects like hotels or spas, companies often rely on procurement expertise for hotel construction projects, as well as sourcing expertise for FFE and OSE.

Key Challenges During Construction Procurement

Procurement is commonly referred to as the make-or-break point of construction and rightly so. Despite one of the best planning, the difficulties during procurement may overwhelm a project, and this has to be taken into consideration.

The complex and common challenges of Construction Procurement are given below:

1. Delays in Supplier Deliveries

Late delivery of beams of steel or concrete can undermine the entire schedule by weeks. Such procurement barriers are usually due to weak supplier interactions and thus logistics planning, or external factors such as delays in ports of calling or transport strikes.

2. Budget Overruns

Material purchase comprises the biggest part of construction expenditure, and as such, having poor cost management can easily lead to cost desertion. Raw material changes and unseen logistics costs can always be a surprise to projects that lack an effective procurement system.

3. Contract Ambiguity

Loosely written contracts or poorly defined contracts provide too much ground to interpret. It may lead to scope disagreements, quality or time issues at a later stage, with the resulting headache of legal and operational wrangles. Such documentation is very important in evading this trap.

4. Supply Chain Disruptions

Construction supply chains often stretch across multiple regions and depend on a tight sequence of manufacturers, distributors, and transport providers. Unlike routine delivery delays, supply chain disruptions are harder to predict and resolve. Without flexible procurement planning and supplier diversification, such disruptions can quickly escalate into major project risks.

Public-Sector Procurement Insight

According to the Pagabo Report 2023, 61% of contractors reported project disruptions due to poorly managed procurement processes.

This highlights how critical structured procurement is across industries. For example, procurement in healthcare operates under strict, rule-based frameworks. Such rigid structures are sometimes regarded as too rigid, but it helps reduce risk, enforce accountability, and improve transparency where taxpayers’ money is involved.

Digital Transformation & Local Sourcing

The world is changing, and with the help of technology, procurement is receiving an important upgrade. Digital procurement is revolutionizing the construction sector. AI-based tools, predictive analytics, and e-procurement platforms streamline sourcing, tracking, and payments. Local procurement supports community development and improves social value.

According to the Pakistan Engineering Council, the PKR 2 billion smart city initiative in Lahore integrated AI-led procurement, achieving 18% cost efficiency compared to traditional methods.

Buy Smart, Buy Fast, Buy Better

There are no longer manual approvals or estimating delivery times. Today, digital procurement systems are reshaping construction sourcing with real-time inventory tracking, reliable suppliers, and AI-powered forecasting.

Predictive analytics in project management helps teams plan budgets and schedules more effectively, since project managers can anticipate shortages.

Rise of Local Procurement & Social Value

Digital procurement is not the only change that is transforming the industry. Local procurement is also gaining attention. By sourcing materials, labor, and services locally, projects can shorten supply chains, reduce delays, lower carbon emissions, and support the local economy.

Construction isn’t just about what is built; it’s about the people who benefit from it. That’s where social value comes in. Public-sector procurement is increasingly giving importance to suppliers that do more than deliver materials. They create jobs, develop local talent, and support community initiatives. This conscious approach to procurement is gaining traction, and it’s here to stay.

How Delta Gulf Overseas Integrates Digital and Local Procurement Strategies

At Delta Gulf Overseas, we work with both strategies. Our purchasing policies combine best-in-class online tools with community-focused principles, whether it’s using smart bidding platforms or collaborating with local vendors. The most efficient approach is the one that is both practical and effective.

As procurement processes evolve, everything else improves too: fewer delays, improved quality, stronger relationships, and buildings that do not merely stand tall, but stand for something.

Strategic Procurement for Mega Projects

Mega projects require strategic procurement planning to consolidate suppliers and manage framework agreements. Large infrastructure, hospitality, and energy projects benefit from long-term vendor partnerships and risk-sharing contracts.

Framework Agreements

These long-term pre-negotiated agreements are with the preferred vendors and offer price stability, provision of access to the supply, and easy procurement of repetitive needs. It should be viewed similarly to a fast-pass lane at each procurement gate.

Supplier Consolidation

The important thing, therefore, is long-term supplier consolidation. Competitive suppliers will expand with your project and handle more responsibility. They co-develop schedules, share innovative knowledge and develop risk management strategies. This is not a thing about corner-cutting; it is about forming stronger supply chains.

Delta Gulf Overseas’ Approach to EPC-Led Procurement and Risk Management

Delta Gulf Overseas LLC manages procurement for large-scale energy projects through EPC-led frameworks, reducing delays and controlling costs. We are involved in the rapid deployment and maintenance of heavy energy installations using an EPC-led framework and risk-sharing clauses. Our strategic procurement will turn your project into the spine of success.

Final Thoughts

Procurement in construction is critical to project success. Proper planning, management, and digital integration can save costs, prevent delays, and improve quality. If your organization wants to improve outcomes, exploring structured procurement strategies and leveraging expert support is key. At Delta Gulf Overseas LLC, our focus is to develop procurement plans that are capable of reducing delays and cost escalation.

Frequently Asked Questions

What is the procure-to-pay process in construction?

The procure-to-pay process involves identifying needs, sourcing suppliers, creating purchase orders, receiving goods/services, and completing payments. Digital tools enhance transparency and cost tracking.

What procurement methods are used in construction?

Methods include Traditional, Design-Build, EPC, Management Contracts, and BOO, each with specific pros and cons for cost, control, and risk.

How much of a construction project’s cost is typically spent on procurement?

Industry averages indicate 40–70% of a project’s cost goes to procurement. Best-in-class processes can improve margins by 5–10%.

What are the common challenges during procurement in construction?

Supply chain disruptions affect 70–80% of firms, with average cost overruns of ~27% and project delays of ~20%. Poor contract clarity and supplier delays are major contributors.

What is digital procurement, and how is it impacting construction?

Digital procurement, including e-procurement, BIM, and IoT, improves efficiency and transparency. BIM adoption can reduce costs by up to 20%, while IoT analytics can predict supply delays and manage inventory effectively.

I love how the post highlights procurement as the backbone of a successful construction project. It really makes you realize just how vital it is to not only source the right materials but also to hire the best contractors for the job. Without a solid procurement strategy, a project could easily fall behind or exceed budget.